To complete the transport lines, DITEC Engineering produces a range of handling units that can be integrated together with conveyor belts or within the production facility.

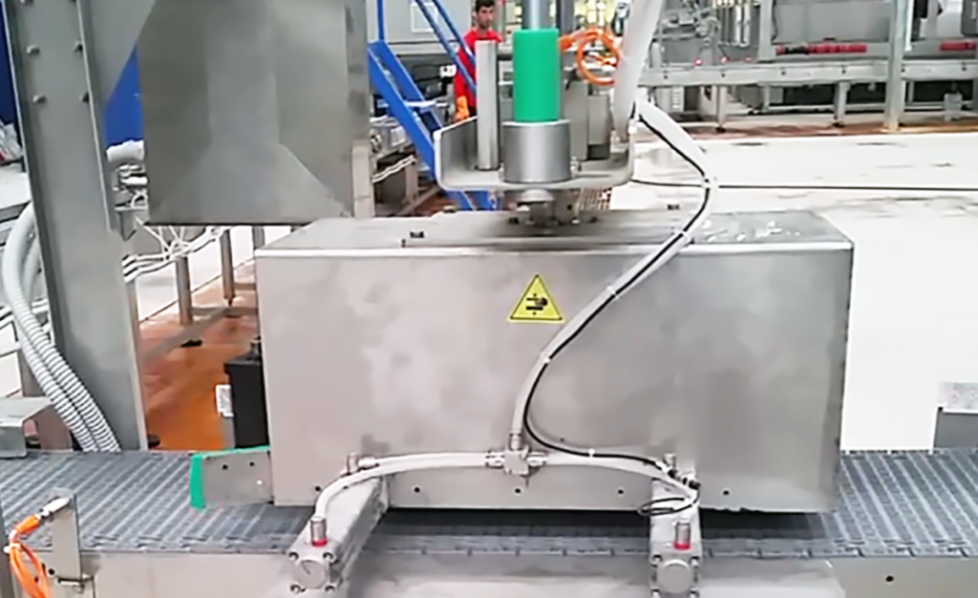

Rotation unit

The rotation unit prepares the battery for the next phase by orienting the poles according to the direction required. The rotation can take place in both directions, with rotations of 90° or 180°.

Transfer unit

This unit allows to combine multiple sections of a transport line making 90° joints, it’s responsible for the belts synchronization and for the transfer from one section to another.

Deviation unit

In order to increase the accumulation capacity, it is possible to use several parallel belts. This unit is used to move the battery from a conveyor to another parallel to the first.

Clocking unit

To accumulate batteries with a specific space between them, to create a buffer of batteries on a belt.

Separation unit

To manage a buffer of batteries, to release them individually according to the next station needs.

All the handling units can be easily integrated with the conveyor belt.