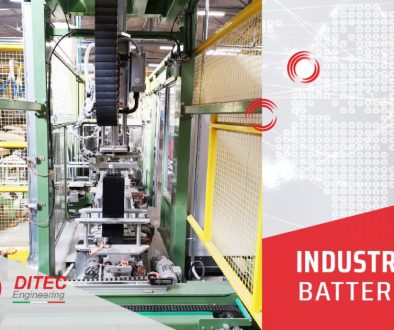

Tank for AGM batteries

The tank conceived and designed for AGM batteries: maximum efficiency, speed and production flexibility.

We have applied all the skills and technologies we have acquired over the years in the field of lead acid batteries to the AGM battery industry. This led us to develop a training tank specifically for AGM batteries, with the same strengths as our tanks:

- Automatic charging and discharging to optimize battery charging performance. Remember: proper battery loading in the tank means optimal yield of convective charging motions.

- Water filling and cooling system

- Automatic air intake

To learn more details about our tanks, read our “formation waterbath” project.

Small size, maximum quality.

The special feature of this machine of ours is its small size. AGM batteries perform best when charged in special small tanks. This leads to an advantage in charging times: the time between acid filling and battery formation is reduced.

The correct size is a key point that should not be underestimated. In fact, the small size allows optimal battery placement. This ensures that heat is evenly distributed throughout the tank and therefore that charging occurs evenly a guarantee of uniform charging among all batteries. The result? High-quality batteries.

Did you know? If you want to learn more about this topic, we also recommend our article “advantages of roller conveyor in water bath formation“

Optimal charge yield and … production flexibility.

Thanks to its size, the AGM battery tub can be shipped already assembled: ready to be connected to utilities and immediately ready for production.

In addition, this machine is also ideal for small batch production that brings production to its maximum flexibility.

- Reduced size, reduced time, reduced consumption.

- Optimized yield, high quality.

If you want to stay up-to-date on our studies, innovations and work, visit our LinkedIn profile.

Moreover, if you want to read more articles visit our news page.