Save energy and resources.

Water emergency and pollution danger: Ditec Engineering ready to respond with cutting-edge solutions to save energy and resources.

The increasing effects of the climate crisis must lead companies, we companies, to reflect on our own environmental impact. Optimizing energy and resource use must be a priority.

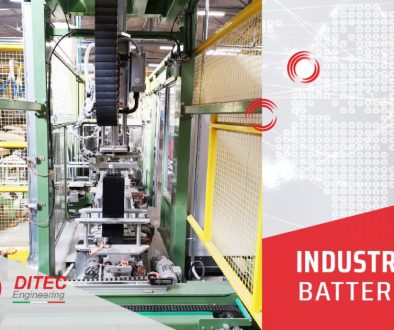

For these needs, our specialists have developed solutions for the battery industry in two main areas:

- The reuse of water

- The elimination of civil works

In the following paragraphs, we will look at how these solutions make the plant state-of-the-art in terms of energy efficiency and optimization of the resources used…let’s save energy together!

The reuse of water

Our state-of-the-art scrubber makes it possible to reuse as much of the same water as possible during the battery formation process. The water is cooled and fed back into the production process, allowing for a twofold benefit:

- Reduction of water required from the aqueduct.

- Recovery of heat from the water.

- The water used is thus drastically reduced. In addition, thanks to the heat recovery system, heat can be generated from the water during the water cooling process.

To learn more about this topic, read our project “air and water treatment” and our article “air and eater treatment: the scrubber“…lest’s save energy!

The elimination of civil works

In order to meet the environmental needs of new production facilities, our machines are developed to need no civil works for their installation. This allows us to:

- Speed up the installation or expansion of the plant

- Reduce the impact on the surrounding environment

- Reduction of bureaucratic time

To learn more, read our project “smart auxiliary equipment”.

We keep up with the needs of the market. Ready to respond to the needs of our customers and related industries.

If you want to stay up-to-date on our studies, innovations and work, visit our LinkedIn profile.

If you want to read more articles visit our news page.