The refreshment bench: a competitive advantage.

In this article we describe an accessory machine that can give a competitive advantage to both manufacturers and distributors of lead acid batteries: the refreshment bench.

Let’s start by briefly defining the function of the refreshment bench: it is a system that allows the recharging of batteries after a long period of inactivity in storage.

From the distributors’ point of view,

having to restore the charge of the batteries before delivery to the Customer means having to send the batteries back to the manufacturer, with a consequent increase in delivery times and in the final cost of the product. Having a refreshment bench can therefore be a competitive advantage for distributors, as it reduces the time and cost for recharging batteries.

From the manufacturers’ point of view,

adding a refreshment bench to their lead acid battery plant gives them a competitive advantage, too. Why? Adding this stand-alone system to your plant means that you don’t have to interrupt your production line when you receive batches of batteries to refresh.

This means maintaining plant productivity and offering prompt service to distributors and Customers who need to recharge their batteries.

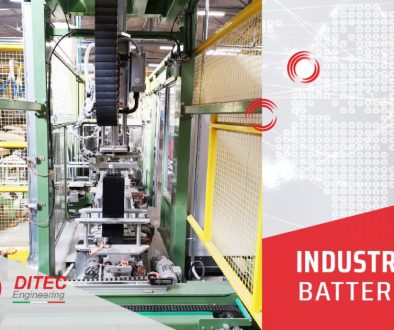

The refreshment stand is a modular machine. This means that several refreshment banks can be put together for greater production efficiency.

The DITEC Engineering refreshment bench comes complete with:

- Fume extractor

- Electrical parts, i.e. charging cabinets with rectifiers

Assisted loading and unloading machinery for raising and lowering pallets of batteries to charge can be added as an optional feature.

Se vuoi rimanere sempre aggiornato sui nostri studi, innovazioni e lavori, visita il nostro profilo LinkedIn.