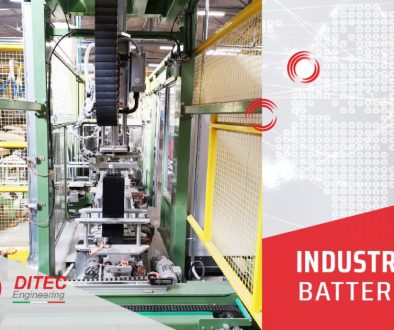

Water baths automatic loading and unloading: an improved system.

This article introduces the system that ensures a uniform spacing of the accumulators at the entrance of the formation water baths.

The following video, showing one of our customers’ premises, demonstrates how our automated system loads accumulators into water bath.

This highly productive system can easily load eight batteries per minute, thanks to the technology of the automatic loading shuttle.

This system is also connected to the water bath by means of a roller conveyor that facilitates the transit of the batteries from the conveyor belts to the machinery where the processing will take place.

The video above shows a fully automatic loading of the machine. In addition, DITEC Engineering also produces a semi-automatic version, in order to meet all market requirements.

Among its many assets, the loading shuttle is made of AISI316L stainless steel, which is particularly resistant to corrosive substances, such as the electrolyte in the batteries.

However, the greatest strength of the system lies in the fact that it is software-controlled and therefore completely customizable.

How does the software improve the performance of the machine?

The software can be set up with different recipes that recognize the type of battery to charge. As a result, the machine can position the batteries at a perfectly equal distance, both horizontally and vertically.

In turn, the batteries’ uniform positioning guarantees better quality charging because it allows the water to be maintained at a constant temperature and equi-distributed on all sides.

The recipes used by the automatic loading shuttle are managed by the global SCADA system. This provides centralized control of the overall formation plant, ensuring better control as well as more efficient production.

If you want to stay up-to-date on our studies, innovations and work, visit our LinkedIn profile.

If you want to read more articles visit our news page.