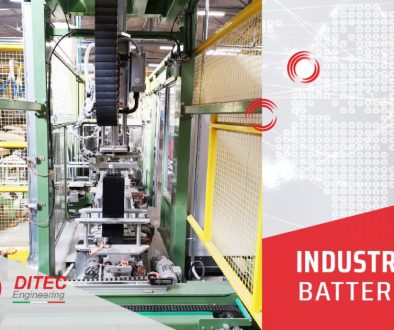

The handling system that facilitates the production process.

Today we are talking about our battery handling system. It facilitates the autonomous performance of the production process.

Moving batteries from one process to the next, or between different plants, is first of all a logistical problem, often tiring and time-consuming.

Therefore, we have developed a solution for these problems: the palletizing island. This machine pallet the batteries so that they can be easily transported to the next process.

Certainly, moving boxes to a pallet manually is a time consuming operation, longer and more expensive process. Such work can create a lot of stress for workers.

Our palletizing systems provide automatic laying of batteries to the pallets, for efficient transportation and storage. The main strengths of palletizing systems are:

- Flexibility: it adapts to different types of batteries. In fact, it is compatible with car, truck and industrial batteries simply by acting on the recipes of the machines.

- Integration: it includes a roller so it’s better integrable within a line. This functionality allows for a high degree of automation.

- Cost saving: it saves time and effort during the production process. A further step towards the optimization of production processes.

A single machine that can improve the efficiency of an entire battery manufacturing plant. A flexible, adaptable system that allows you to achieve a higher level of automation.

To learn more about this topic, read our project “Paletizing system”.

If you want to stay up-to-date on our studies, innovations and work, visit our LinkedIn profile.

If you want to read more articles visit our news page.